We’re pleased to announce that Brick Simulator is now fully compliant with brand new EN 1745 2012.

Frame Composer, our EN ISO 10077-1 window transmittance simulator (for Windows and Mac OSX) version 2.0.0 is out! Here you are the list of major changes:

- completely new report system;

- curved elements;

- label tool;

- new GUI;

- freehand mode.

Please go to Frame Composer page for more information.

Frame Simualtor, our window transmittance simulator (for Windows and Mac OSX) version 2.0.9 is out! Here you are the list of major changes:

- settings file can be saved to a custom folder;

- conditional labels;

- improved printed viewports;

- import/export more than one texture a time;

- views window minimized at run time;

- various bug fixes.

The new viewer can be downloaded at Frame Simulator | Window Transmittance.

We’re very pleased to announce that Mold Simulator, our thermal bridge simulator (for Windows and Mac OSX) 2.0.9 is out. Here you are what’s new:

- settings file can be saved to a custom folder;

- conditional labels;

- improved printed viewports;

- import/export more than one texture a time;

- views window minimized at run time;

- various bug fixes.

The new viewer can be downloaded at Mold Simulator | Thermal Bridge.

In this article we’ll discuss thermal lag, an important value to take under consideration when analyzing walls and, more in general, building structures. We’ll use our thermal bridge FEM software, Mold Simulator Dynamic, to compute thermal lag in accordance with EN ISO 13786.

In case of simple structures (i.e. a set of homogeneous layers) thermal lag can be analytically evaluated using EN ISO 13786 formulae, but in more general situations a FEM simulation is required.

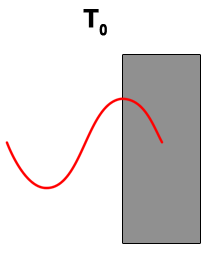

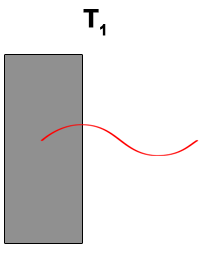

Thermal lag represents a structure’s thermal mass in terms of time; to make it simple, it’s how long it takes to the heat wave to pass through a building structure.

|  |

| T0: time when temperature is at its maximum on external surface. A sinusoidal heat wave is applied to external surface. | T1: time when temperature is at its maximum on internal surface. The heat wave has been delayed and faded. |

Thermal lag = T1 – T0 in hours

To have a better understanding of this subject please download this sample for Mold Simulator Dynamic:

![]()

You need Mold Simulator Viewer (free) to open it.

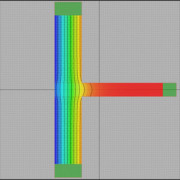

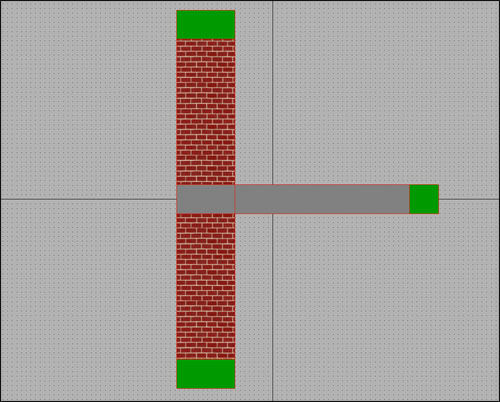

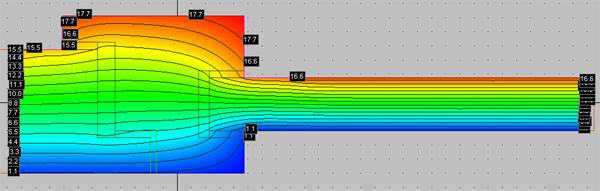

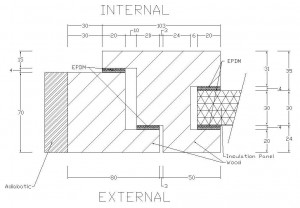

In this brief tutorial we’ll show you how to computer linear thermal transmittance of a typical thermal bridge: a junction between a wall and a floor. We’ll use Mold Simulator as FEM software for its analysis.

Thermal bridge

The structure is in contact with external environment (on the left) and internal environment (on the right).

In this case, the thermal bridge is caused by floor; a way to evaluate it is to compute its linear thermal transmittance, ψ (psi) in W/mK.

Linear thermal transmittance

This value represents the difference between the theoretical configuration (just a wall) and the real one (a wall with an intersecting floor).

| Theoretical configuration | Real configuration |

|  |

| Wall length (l): 1.1 m Wall transmittance (U): 1.0980 W/m²K (computed simply considering wall’s material properties) Thermal conductance (L2D): U x l = 1.2078 W/mK | Wall length (l): 1.1 m Wall transmittance (U): 1.2548 W/m²K (FEM simulation with Mold Simulator) Thermal conductance (L2D): U x l = 1.3803 W/mK (FEM simulation with Mold Simulator) |

You need Mold Simulator Viewer (free) in order to view it.

This is the second part of a tutorial about window transmittance computation using Frame Simulator, our FEM simulator available for Windows and Mac OS X. For the first part, please see Window Transmittance – part 1.

In this tutorial we’ll use the following abbreviations:

- LMB = left mouse button click;

- MMB = middle mouse button click;

- RMB = right mouse button click.

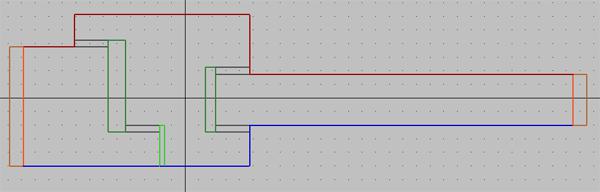

Borders definition

Please click “Boundary” tab and select “Internal”; now click on ![]() button and LMB over one of the lines in contact with intern environment. Similarly, select “External” please click

button and LMB over one of the lines in contact with intern environment. Similarly, select “External” please click ![]() button and LMB over one of the lines in contact with extern environment.

button and LMB over one of the lines in contact with extern environment.

In current project, borders should look in this way:

Moreover, please make sure to have selected ![]() flow direction in “Lines” tab.

flow direction in “Lines” tab.

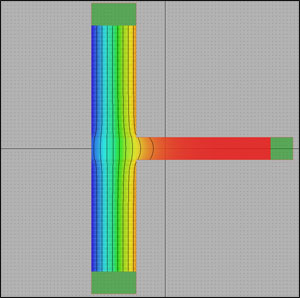

Simulation

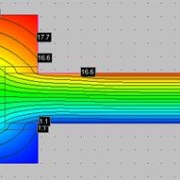

Please click “Simulation” tab and wait that the software performs all the necessary computations. At this point, you can select different types of view: heat flow, temperature, isotherms, etc.

The values required by ISO 10077-2 standard, window transmittance and Lf2D, are shown in “Results” table.

As you have seen, the way to window transmittance following ISO 10077-2 standard is extremely easy with Frame Simulator. We’re planning some more tutorials and articles, so stay tuned!

The viewer version of Frame Simulator, our FEM software for window transmittance computation, is now available for Mac OS X.

We’re extremely pleased to announce that we’ve released Mold Simulator for Mac OS X! Finally a new Mac FEM software for thermal bridge analysis. On Mold Simulator page you’ll also find the new 2.0.8 version.

The purpose of this tutorial is to introduce the basic functions of Frame Simulator, through a step by step development of a simple project regarding a wooden frame. The main result we want to get is to compute window transmittance applying ISO 10077-2.

Here you are the project:

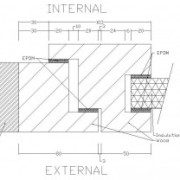

Typical wooden frame of a window.

- “ITERNAL” is the frame’s part in contact with intern environment;

- “EXTERNAL” is the frame’s part in contact with extern environment;

- “EPDM” has a conducibility of 0.25 W/(mK);

- “Wood” has a conducibility of 0.13 W/(mK).

Window Transmittance

Insertion of project in Frame Simulator

In this tutorial we’ll use the following abbreviations:

- LMB = left mouse button click;

- MMB = middle mouse button click;

- RMB = right mouse button click.

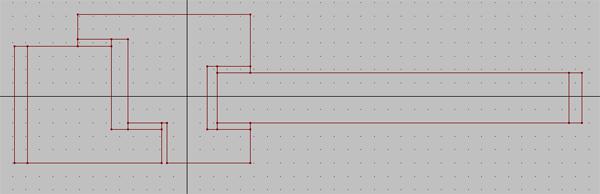

1 – Lines insertion

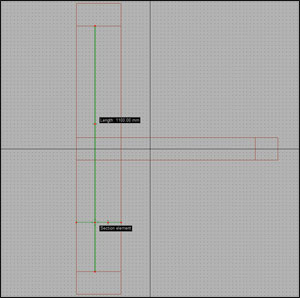

Please run the software. The main interface is composed by tabs representing the various phases of project insertion and by a viewport showing frame’s 2D section.

First of all you need to insert the lines composing the frame; this can be done using the tools in the “Lines” tab or you can simply import a DXF file. This should be the result:

Lines of wooden frame

- Glazing must be replaced with an insulation panel at least 190mm long;

- The end of the insulation panel must be in contact with an adiabatic surface.

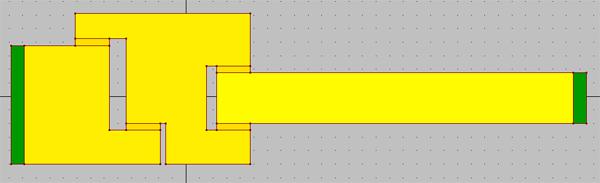

2 – Areas properties insertion

At this point you have to insert the properties of all the areas. Please click on “Areas” tab to enter in areas insertion mode.

Click “Fill area” button and select material type (Standard, Adiabatic, Insulation, Transparent, Glazing gas). In case of standard material, please insert conducibility and emissivity. Usually emissivity is 0.9, except for special materials. LMB in the middle of the areas that you want to create with specific properties.

Areas should look like the following picture:

Areas of wooden frame